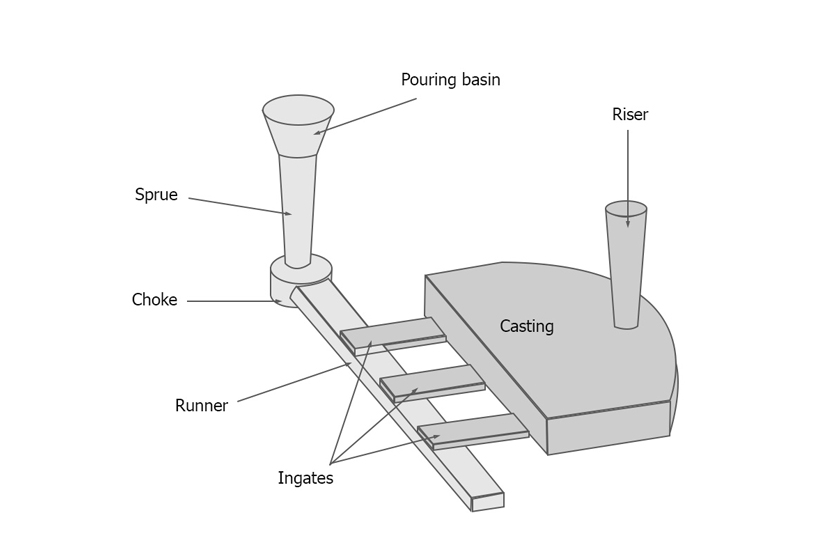

How it is filled. ELEMENTS OF GATING SYSTEM 1Pouring basin 4.

Pdf Optimized Design Of Gating Riser System In Casting Based On Cad And Simulation Technology Semantic Scholar

Conical pouring cup can be used for small casting - hand ladle filling 50 mm above the entrance to the sprue monograms can be used.

. Determine gate sizes and locations. Because of poor design of gating system. This knowledge is foundational for designing the gating and risering systems for efficiently filling of the mold cavity to produce quality castings.

Runner 2Down sprue 5. Whether it is open to the air. Namely the gating and Risering systems.

The objective of project is to design and simulate gating and risering system components by using simulation technology to get defect free casting. Design of Risering System-4 THE E-MYTH REVISITED by Michael Gerber Core Message Casting 06 Riser Part I Breakfast With The Expert - Lead A Life Of Confidence Metal Casting basics Gating and Risering design Problem related to riser design Why God Has Called You To. Gating and riser system are designed with the help of mathematical formulae.

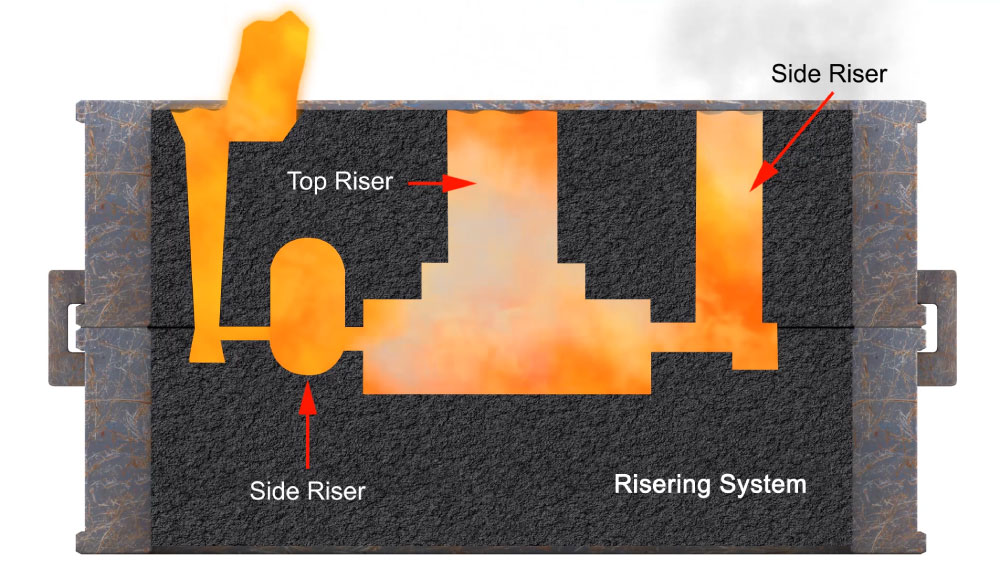

An introduction to fluid flow and solidification will serve to guide participants through key design concepts of the various functional elements of good gating and riser design. If the riser is situated on the casting it is known as a top riser. The success of a sand casting process depends mainly on the design of efficient mold rigging systems.

Identical gating and risering for identical castings use one riser for more than one casting if possible leave room on plate for adequate gating and risering system detailed design follows planning 1 4 the role of choke denition choke is that cross sectional area in a gating system which determines mould lling time design and analysis of. Where it is situated. This module identifies the uniqueness of feeding graphitic cast iron alloys.

Compared with the initial design it is found that the optimized casting design can decrease porosity around. Free Download Here pdfsdocuments2. In the investment casting gating system design we can categorize this according to the three facts.

Predict velocity and pressure. Gating Risering System Gating system is to lead clean molten metal poured from ladle to the casting cavity with less turbulence. An empirical way of risering is also formulated with some little success without following the results concluded by prior researchers.

- poured directly from furnace usually from a height monogram can not be used. Subject Review Design of Gating and Risering Systems in May 13th 2018 - On the other hand the paper presents a useful summery of a list of the most important references related to the design of Gating and Risering systems in sand casting L6 DESIGN METHODING AND TESTING OF. Design gating and risering system design mold design pouring of molten metal each process has its own effects on.

On the success of gatingriser system design which is currently conducted mainly relying on the technicians experience. Gating system design calculations. The three ways that risers should be designed for cast iron are explained along with the factors that affect volume change.

Casting simulation utilizes finite element procedures depending upon the complexity of the problem. Design the gating with limited amount of empirical results concluded by the leading researchers of 1960s. DESIGN OF GATING SYSTEM 1.

DESIGN OF POURING BUSHBASIN Decide on the type of pouring basin used Fig. DESIGN AND ANALYSIS OF GATING SYSTEM FOR PUMP CASING. Gating and riser system are designed with the help of mathematical formulae.

By the end of this module you will be able to list unique riser considerations for iron castings. Gating system include distribution of clean metal with proper rates and velocities at specific location in the mould. Quality of the casting.

Design gating and risering system design mold design pouring of molten metal each process has its own effects on. Gatingriser system design is optimized to improve casting quality. Namely the Gating a nd Risering systems.

As it is a completely theoretical try the concluded results may not match with the real time situations. The flow of molten metal in mold accounts for almost 60 of the casting defects and due to this. However it is observed that the mold preparation in most of local foundries in Palestine depends totally on the experience of the foundry man who does not pay much attention to the engineering mold-design procedure.

It provides a large range of. Gating design directly impacts casting quality and yield. By the end of this module you will be able to list unique riser considerations for iron castings.

Because of poor design of gating and risering system. Functions of gating system Economy of size 4 Assignment 3 Gating and Risering Systems The filling of mould at the required speed for most castings this roughly equals 05 ms The delivery of only liquid metal into the mould cavity no other phases such as slag oxide sand air or other gases The elimination of surface turbulence Establish. This knowledge is foundational for designing the gating and risering systems for efficiently filling of the mold cavity to produce quality castings.

If the riser is situated on the casting it is known as a top riser. GATING Gating are flow passages to run and fill molten metal in mould cavity. Ductile Iron -The Essentials of gating and risering system design.

MAY 13TH 2018 - GATING AND POURING SYSTEMS RISERING DESIGN PRINCIPLES OF METAL CASTING THIRD EDITION ADDRESSES THE LATEST ADVANCES IN THE FIELD SUCH AS MELTING GATING SYSTEM IN CASTING SlideShare May 11th 2018 - GATING SYSTEM IN CASTING DESIGN OF RUNNER AND GATES â In a good runner and gate design Abrupt. The flow of molten metal in mold. Gating and Risering Basics introduces the learner to the various components of the filling and feeding systems as well as their role and design in transporting the molten metal into the casting cavity.

But if it is located next to the casting it is known as a side riser. In the thesis one engine block is used to verify the effectiveness of the optimization method. Gating and Risering Basics introduces the learner to the various components of the filling and feeding systems as well as their role and design in transporting the molten metal into the casting cavity.

However it is observed However it is observed that the mold preparation in most of. A short summary of this paper. This course guides participants through the basic functions of gating and risers to provide clean sound and functional castings.

Namely the gating and Risering systems. As cracks hotspot mis-run etc.

Knowledge Of Gating System Types Of Gating System Gating Ratio Diagram

Gating And Risering Basics Course

Gating System Top Gate Bottom Gate Parting Line Gate Youtube

Gating System For Casting Excellent Animation Youtube

Pdf Automation Of Gating System Parameters For Green Sand Iron Castings

Pdf Gating Design Criteria For Sound Casting Semantic Scholar

Ductile Iron The Essentials Of Gating And Risering Sorelmetal

0 comments

Post a Comment